Hotline:

0086-769-8601-0360

Fax:0086-769-8180-2808

Business Contacts:

Mr. Huang: 0086-133-1667-5312

Domestic business:

E-mail: sales@zldcpump.com

Business and technical support:

Mr. Huang: 0086-133-3268-3563

E-mail: rd@zldcpump.com

Mr. Huang: 0086-132-3837-9488

E-mail: complaint@zldcpump.com

Zip code: 523290

Address: Zhonglong Pump Industry, 2nd Floor, No. 10 Hengling Street, Hengjiao, Shijie Town, Dongguan City

The brush less magnetic pump is a kind of non-contact torque transmission through magnetic drive, so that the static seal can replace the dynamic seal, making the pump complete, solving the problem of "running, emitting, dripping and leaking", eliminating the hidden danger of flammable, explosive, toxic and harmful media leaking through the pump seal in the refining and chemical industry, and effectively ensuring the physical and mental health and safety production of employees.

Working principle of bldcwater pump

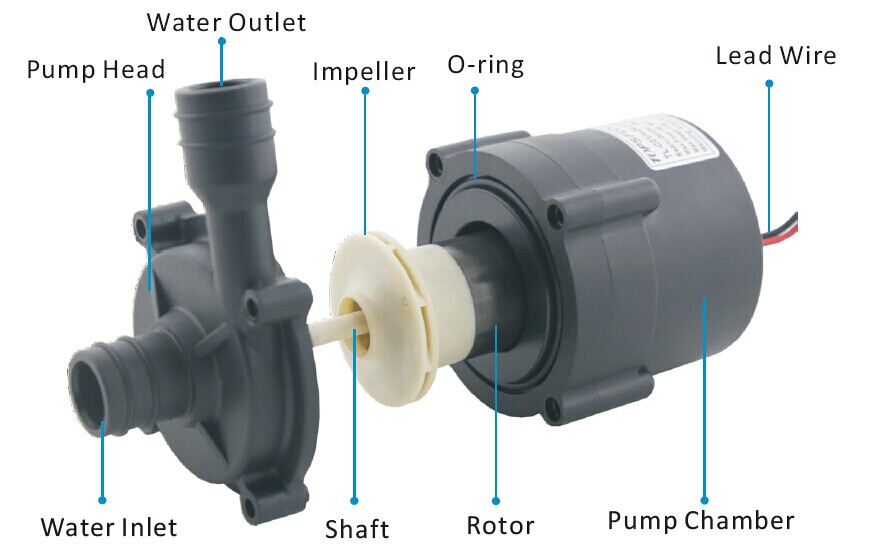

Before we understand the working principle, let's take a look at the structure of the brushless DC magnetic drive pump. The magnet and impeller of the BLDCM drive pump are injection molded into a whole, thus forming the rotor of the motor. There is a shaft sleeve directly injection molded in the middle of the rotor, which is fixed in the shell through a high-performance ceramic shaft. The stator and circuit board of the motor are filled and sealed in the pump body with epoxy resin glue. There is a thin-wall isolation between the stator and the rotor, which does not need to be equipped with the traditional mechanical shaft seal. Therefore, the rotor of the motor is Completely sealed.

The brush less magnetic pump is a kind of non-contact torque transmission through magnetic drive, so that the static seal can replace the dynamic seal, making the pump complete, solving the problem of "running, emitting, dripping and leaking", eliminating the hidden danger of flammable, explosive, toxic and harmful media leaking through the pump seal in the refining and chemical industry, and effectively ensuring the physical and mental health and safety production of employees.

Working principle of bldcwater pump

Before we understand the working principle, let's take a look at the structure of the brushless DC magnetic drive pump. The magnet and impeller of the BLDCM drive pump are injection molded into a whole, thus forming the rotor of the motor. There is a shaft sleeve directly injection molded in the middle of the rotor, which is fixed in the shell through a high-performance ceramic shaft. The stator and circuit board of the motor are filled and sealed in the pump body with epoxy resin glue. There is a thin-wall isolation between the stator and the rotor, which does not need to be equipped with the traditional mechanical shaft seal. Therefore, the rotor of the motor is Completely sealed.

Tel: 0086-769-8601-0360

Fax: 0086-769-8180-2808

URL: www.zimws3.com

Address: Zhonglong Pump Industry, 2nd Floor, No. 10 Hengling Street, Hengjiao, Shijie Town, Dongguan City